At anchor, Mt. Hartman Bay, Grenada

Imagine a large vat of pure, liquid cocoa. It probably sounds pretty good. Actually, no, it's extremely bitter. But the cocoa in this vat goes on to become high quality, very tasty, Grenadian chocolate.

Imagine a large vat of pure, liquid cocoa. It probably sounds pretty good. Actually, no, it's extremely bitter. But the cocoa in this vat goes on to become high quality, very tasty, Grenadian chocolate.Recently, we went on an island tour with two other boats, Neptune II and Avatar, being shown around by our wonderful tour guide, Cutty. On this tour, we went to two of the chocolate factories on the island: The Grenada Chocolate Factory, and the Jouvay Chocolate Factory.

When I say factory, you may think of a large, clean building with automated machines making chocolate. This is not how it is here in Grenada. Rather, these "factories" still use human labor and many of the old fashioned chocolate-making processes. There are a collection of machines that work independently. Liquid cocoa is transferred machine to machine by humans. Humans sort the good cocoa beans from the bad. So while it is a factory, it's not quite a factory one might think of in the US.

Cocoa beans are found inside large cocoa pods, which grow anywhere on the trunk or branches of a cocoa tree. There are two kinds of cocoa pods: green ones which turn yellow when they're ripe, and purple ones which always stay purple. The color is the only difference between the pods. Inside a cocoa pod is anywhere from 20 to 30 cocoa seeds, each of which is covered in a white slimy substance. This substance is sweet and

very tasty. Cutty said that back when Grenadian families were

very poor, the kids would walk home from school for lunch, suck on some

cocoa seeds, and then walk back to school.

|

| These beans are drying on a tarp in the street outside a woman's house. She will use the beans to make cocoa balls (for chocolate tea) that she will sell. |

The first steps of the chocolate-making process are done by the cocoa farmers. Once they pick the ripe pods, they ferment the seeds for eight days in a large wooden box with banana leaves over the top. This being in the Caribbean, the inside of the box gets very hot, hot enough to extract all the juices from the seeds. The seeds need to be turned every two days. After the fermentation process, the seeds dry in the sun for six days. After this, the farmers hand the seeds off to the chocolate factory.

|

| The sorting machine at Jouvet |

|

| The hand-sorting table at Jouvet and with the fermented and dried cocoa beans |

The nibs are then ground up and made into a liquidy paste. From there they are taken to the melanger, which adds sugar to the chocolate. Though they are generally the same, the chocolate factories have slightly different processes. For example, the Grenada Chocolate Factory has a step in which they use a heavy press-like machine to separate the oil from the cocoa to extract the cocoa butter. The cocoa butter replaces milk in the chocolate. The last step is the refiner, or conch, in which the chocolate is heated at an extremely high temperature and mixed. The Conch is what gives the chocolate its flavor, and so the "secret recipe" of the chocolate factories depend on the temperature and mixing process of the Conch.

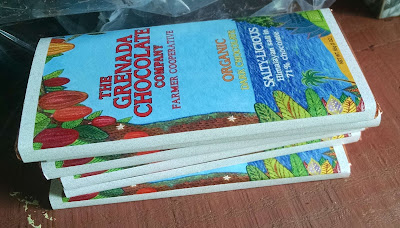

They gave us samples at both chocolate factories, and the chocolate was excellent, ranging from around 60 - 80% cocoa content. The Jouvay Chocolate Factory also made some tasty nutmeg chocolate, and the Grenada Chocolate Factory made sea salt chocolate.

Here's a video of a little bit of our tour at the Grenada Chocolate Factory:

Post a Comment